Neodymium magnets or powerful magnets are permanent magnets with the highest strength and high coercivity. It is the strongest magnet on the market and the most widely used in the industrial sector.

The production of neodymium magnets has a low resistance to corrosion so it has a protection or coating to ensure the maintenance and durability of the magnet over time, this coating will prevent it from losing its properties and being affected by corrosion and external chemical agents.

The coating of the neodymium magnet can be epoxy, nickel, zinc, copper, and others. Below, we can see a table of neodymium magnet qualities in which we find the remanence, the coercive force, the working temperature, and the minimum and maximum resistance of each type of neodymium quality.

Most neodymium magnets, due to their high remanence and coercivity, mentioned above, can be used in the electronics sector.

Neodymium magnets or strong magnets have a high density and a degree of magnetisation of 5,000 gauss and 52 MGOe. The higher the grade, the more magnetisation the magnet will have, as it is made of neodymium magnets, the letter in the grade is an N. Neodymium magnets have a degree of magnetisation that can vary from N27 to N52. Neodymium magnets have a higher price than ferrite magnets because of the complexity of obtaining their raw material.

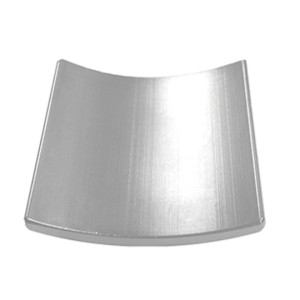

All neodymium magnets are anisotropic and therefore only can magnetise in one direction. The magnetisation of square neodymium magnets is diametrically magnetised.