Neodymium rings are similar to neodymium discs with the difference that they have an opening in the core producing a magnetic field. Neodymium ring magnets are the most widely used type of magnet due to their holding power. The most common qualities that makeup neodymium rings are N35-Ni and N25-ZN.

Neodymium rings or rings are characterized by their high performance and their high power. We can allocate this type of neodymium magnets to various sectors such as automotive and medicine among others; more specifically microphones, door locks, jewelry, motors, wind turbines, magnetic separators, and speakers…

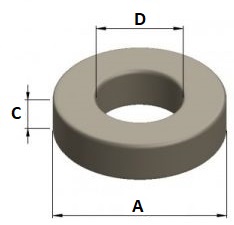

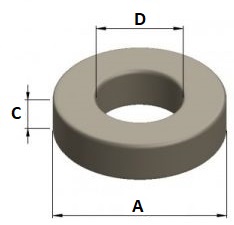

Standard sizes:

The standard size that we manufacture neodymium rings can be seen below. Like the other forms of neodymium magnets, we must keep in mind that we will not need a large size to obtain a great holding force since we are working with neodymium, the permanent magnet with the strongest magnetic force. Likewise, if another size is required, we can manufacture them according to the client's needs.

| Size range |

A (mm) |

C (mm) |

D (mm) |

| 5-240 |

1-100 |

1-210 |

Format:

Neodymium rings have a low corrosion resistance, so they need a nickel coating to protect the magnet from external factors.

Due to its central hole, the neodymium rings offer a greater grip than other forms of magnets such as neodymium blocks. Applications such as 3D printing, and elements for the manufacture of drones and jewelry among others.

Maximum working temperature:

The ring-shaped neodymium rings have a resistance of 80ºC to be able to work with them and manipulate them according to the need that we want and the application to which we are going to allocate it.

View 360º

Click on the image, hold and turn.

Recent Comments