Description and characteristics

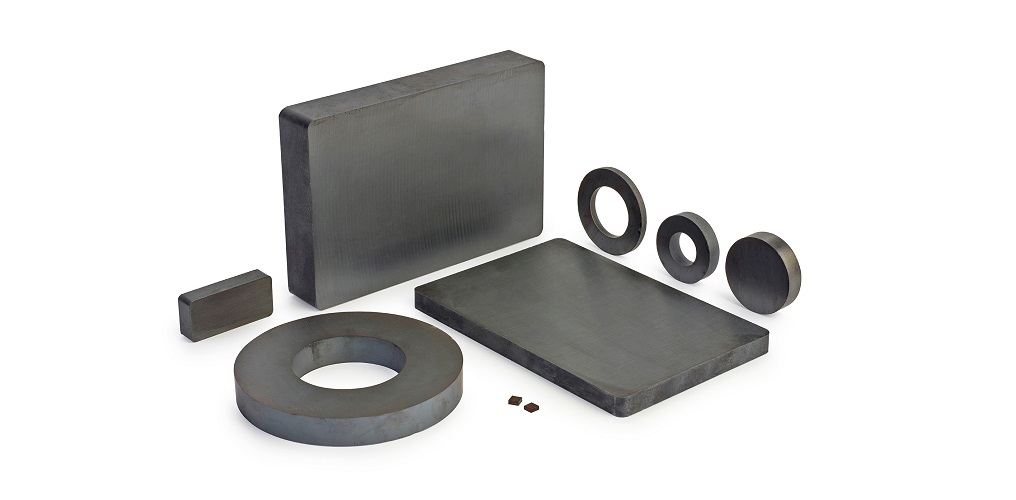

Square, ring, disc and segment magnets are the most common types of permanent magnets produced by injection moulding, and they can be produced economically by this method.

In addition to the geometries mentionned, permanent magnets can be produced in different shapes, which should wherever possible be included as part of the moulding. Subsequent modifications to shape are only possible with expensive machining operation and diamond tools. This applies to holes, chamfers, indentations, etc. In this context is should be noted that gores, openings etc, can only be produced in direction of pressing. With anisotropic magnets is not possible to provide these transverse to the preferred direction.

Machining Procedures For Magnets

Square magnets are usually pressed in a tool, sintered (heat treated) and, if necessary, ground to exact tolerances. For special applications it is necessary to machine the magnets on all sides in order to meet dimensions or weight tolerances. These machining stages have to be accomplished with great care because of the high degrees of brittleness and hardness of the material. If it is really necessary to machine all side of a magnet, finishing by sawing or cutting is often more favourable. The surface quality and tolerance of the separated faces correspond to those of ground magnets and further machining is unnecessary. Small magnets with exacting tolerances can be produced by this process alone.

Recent Comments