Neodymium magnetic bases are useful tools in a variety of applications in industry, electronics, science, and other fields. These bases are made from neodymium magnets, which are the strongest permanent magnets commercially available. Neodymium is a rare earth magnetic material that is used in the manufacture of these magnets due to its unique magnetic properties.

A neodymium magnetic base consists of a neodymium magnet covered by a metal casing that acts as a contact plate. The metal casing may also have a threaded hole for easy attachment to a variety of objects. The neodymium magnetic base is commonly used to hold metal objects in place securely and stably on metal surfaces. The magnetic strength of these bases is such that they can withstand heavy loads and offer superior resistance to vibration and shock. Neodymium magnetic bases are useful tools in a variety of applications in industry, construction, automotive, and electronics. These bases consist of a powerful neodymium magnet attached to a metal housing that can be secured to a surface using a clamping mechanism, such as a locking knob or quick-release lever.

The neodymium magnetic base is a very useful device in a wide variety of industrial and commercial applications, where a strong, high-quality magnet is needed to ensure the attachment of heavy objects and keep them in place.

One of the most notable advantages of neodymium magnetic bases is their ability to adhere to flat and curved surfaces, making them very useful in manufacturing and construction environments, especially in the welding and assembly of metal parts. The magnetic base can be easily moved from one surface to another, allowing for greater flexibility and efficiency in the work process.

Neodymium bases also known as container magnets have an axial magnetization, in addition to having the ability to implant 18 magnetic poles.

The container magnets are protected with a nickel coating and can be used in various sectors such as sensors, and turbines...

In electronics, neodymium magnetic bases are used to hold circuit parts and components in place during assembly and soldering. These magnetic bases are particularly useful in repair and maintenance applications, where components need to be held in place while work is being done.

Neodymium magnetic bases are used in many applications, such as machinery manufacturing, automotive, electronics, construction, medicine, and scientific research. In machinery manufacturing, neodymium magnetic bases are used to hold workpieces to the surface of a machine, allowing for precise machining. In the automotive industry, these magnetic bases are used to hold tools and workpieces while performing repairs and maintenance.

In medicine, neodymium magnetic bases are used to hold instruments and tools during surgical procedures. These magnetic bases are especially useful in laparoscopic surgery procedures, where precise and stable holding of instruments in a limited space is required. In scientific research, neodymium magnetic bases are used to hold objects during experiments and tests. Despite their great usefulness, it is important to keep in mind that neodymium magnetic bases can represent a danger to people with pacemakers or medical implants. Neodymium magnets can interfere with the operation of these devices and should be kept away from them.

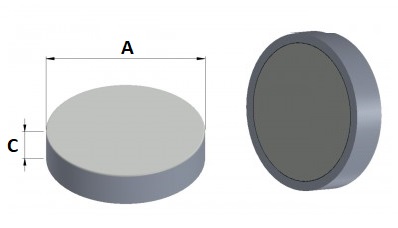

Standard sizes:

| Code |

A (mm) |

C (mm) |

Weight (g) |

Strength (Kg) |

Strength (N) |

| BASN01412 |

6 |

4.5 |

1 |

0.5 |

5 |

| BASN01413 |

8 |

4.5 |

1.5 |

1 |

10 |

| BASN01406 |

10 |

5 |

2.5 |

1.5 |

15 |

| BASN01407 |

13 |

4.5 |

4.5 |

3 |

30 |

| BASN01408 |

16 |

4.5 |

6.5 |

7 |

70 |

| BASN01524 |

20 |

5 |

15 |

12 |

120 |

| BASN01410 |

25 |

7 |

22 |

20 |

200 |

| BASN01411 |

32 |

7 |

40 |

26 |

260 |

*The force is calculated on a 10 mm sheet.

Format:

Upon request, neodymium bases can be supplied in any other dimension.

Maximum working temperature:

The standard working temperature of neodymium magnetic bases is 80°C. For a higher working temperature, contact our sales department.

View 360º

Click on the image, hold and turn.

Recent Comments