Neodymium cylindrical bases are magnetic systems, recommended to hold pieces in reduced space in which a lot of force is required, in which a powerful magnet is inserted into a cylindrical steel container, which when close to a thick iron surface , makes it easier to increase the holding force of the magnet.

Neodymium cylindrical magnetic bases are the ideal means for holding parts in very confined spaces, where a great magnetic force is needed. Neodymium bases are created from neodymium magnets, characterized by being the most powerful permanent magnet on the market and with a great capacity to tolerate the force to which it is subjected. However, the cylindrical Neodymium base has a low resistance to corrosion, which is why we mostly find them with a coating.

Neodymium cylindrical magnetic bases are useful tools in many applications, from industry to home. These bases are made of a highly magnetic neodymium material that allows them to hold heavy metal objects with ease.

Neodymium is a type of rare earth magnet that is known to be the strongest magnet commercially available. This makes it an excellent choice for manufacturing cylindrical magnetic bases. Cylindrical Pot Magnets are capable of holding objects with an incredibly strong and stable magnetic force, making them a popular choice for a variety of applications.

In addition to their magnetic strength, neodymium cylindrical magnetic bases are corrosion and wear-resistant, making them ideal for use in harsh environments. They are also easy to clean and maintain, making them an excellent choice for applications where hygiene is important.

However, cylindrical Pot Magnets is important to note that cylindrical neodymium magnetic bases can be dangerous if not handled correctly. Because of their magnetic strength, it is important to make sure they are out of the reach of children and people with pacemakers. It is also important to handle them carefully to avoid injuries.

The cylindrical neodymium magnetic base is usually used in dry interior places since they have a low oxidation resistance, however, it is usually used with a nickel or rubber coating to provide protection and durability over time. In addition, it increases corrosion resistance.

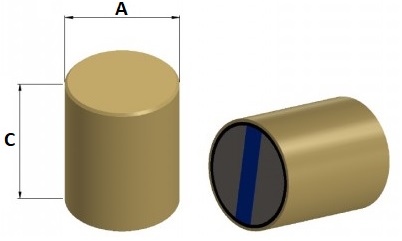

Standard measurements:

| Code |

A (mm) |

C (mm) |

Weight (g) |

Strength (Kg) |

Strength (N) |

| BASN01420 |

6 |

20 |

45 |

1 |

10 |

| BASN01421 |

8 |

20 |

8 |

2.5 |

25 |

| BASN01414 |

10 |

20 |

12.5 |

5 |

50 |

| BASN01415 |

13 |

20 |

20 |

8 |

80 |

| BASN01416 |

16 |

20 |

32 |

15 |

150 |

| BASN01417 |

20 |

25 |

60 |

28 |

280 |

| BASN01418 |

25 |

35 |

135 |

45 |

450 |

| BASN01419 |

32 |

40 |

250 |

70 |

700 |

*The force is calculated on a 10 mm metal plate.

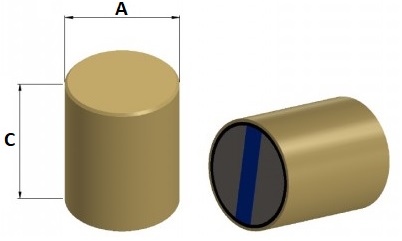

Format:

The neodymium cylindrical container is a cylindrical piece of iron and with an outer layer of paint, the load applied to the magnets will be less. This cylindrical neodymium base the greater the height and diameter of the magnet, the greater the force.

Maximum working temperature:

The standard working temperature is 80°C. For higher working temperature, please contact our sales department.

View 360º

Click on the image, hold and turn.

Recent Comments