Direct current electromagnet (IMAVEM):

These electromagnets in their standard models are manufactured at a voltage of 24 vdc, but on demand they are manufactured at any voltage, for their operation they require power supply, when this is missing the generated magnetic field disappears.

In their standard mode they are for continuous operation, they are manufactured with other operating factors.

These electromagnets are used for robotic automation, handling, safety, etc.

Ferromagnetic objects are attracted and held by passing an electric current through the coil of the electromagnet. When the supply current is switched off, the retained object is released. When working with suspended loads, safety regulations must be observed.

Features:

Degree of protection IP65

Thermal Class B (130)

Rated voltage 24V DC

Normalised Duty cycle: ED 100%.

For other voltages, ED or sizes, please consult us.

Such electromagnets must be activated only in contact with the metal object to be held. They are intended for intensive operation without limit of movements and in permanent service. Their main benefit is a strong holding force with moderate power consumption.

Coils standardized 24 VDC

ED. 100% continuous operation.

Standard terminals included free-of-charge, for all sizes.

Supply possibilities on request:

- With connection cables. (Standard model)

- With connector, from model IMAVEM50 or higher (Optional) – The connector has 4 options for positioning (4 × 90º).

The following table gives the holding force values (Fm) according to the air gap (.DELTA.L) and measured under the following conditions:

- Dc supply (DC).

- Flat holding piece (<3μ roughness) in AºSt37, the thickness of which is indicated in the table and dimensions to be greater than the magnetic face of the electromagnet.

- 20 ° C ambient temperature.

- Coil stabilized at its working temperature.

At higher temperatures, the magnetic force (Fm) can decrease.

| Model |

Code |

P a 20ºC (W) |

e (mm)

Thickness of the workpiece |

Air gap (mm) δL |

|

| 0 |

0.1 |

0.2 |

0.5 |

1 |

Magnetic Forces Fm (N)

|

| VEM-20 |

ELEE00012 |

1.6 |

1 |

14.5 |

3.8 |

1.6 |

0.3 |

|

| 3 |

27 |

5.7 |

2.6 |

0.35 |

|

| VEM-25 |

ELEV01740 |

2.5 |

1 |

45 |

26 |

11 |

3 |

1.5 |

| 3 |

160 |

37 |

11.5 |

3 |

1.9 |

| 6 |

170 |

39 |

11.5 |

3.2 |

1.9 |

| VEM-25 |

ELEE0007 |

3.2 |

1 |

35 |

28 |

14.5 |

4 |

2 |

| 3 |

150 |

50 |

15 |

4 |

2 |

| 6 |

160 |

51 |

15.2 |

4 |

2 |

| VEM-30 |

ELEE0020 |

4 |

1 |

37 |

24 |

18 |

6 |

1.5 |

| 3 |

170 |

80 |

40 |

9.5 |

1.6 |

| 6 |

190 |

90 |

45 |

12 |

2 |

| VEM-40 |

ELEE00017 |

5.6 |

1 |

38 |

30 |

24 |

13 |

4 |

| 3 |

300 |

203 |

133 |

27 |

4.5 |

| 6 |

400 |

245 |

160 |

30 |

5 |

| VEM-50 |

ELEE00002 |

6.5 |

1 |

40 |

32 |

30 |

25 |

15 |

| 3 |

320 |

235 |

185 |

65 |

16 |

| 6 |

500 |

370 |

240 |

68 |

20 |

| VEM-65 |

ELEE00014 |

10 |

1 |

45 |

40 |

30 |

25 |

15 |

| 3 |

310 |

290 |

250 |

148 |

40 |

| 6 |

830 |

660 |

500 |

164 |

46 |

| 10 |

980 |

750 |

560 |

190 |

50 |

| VEM-80 |

ELEE00013 |

15 |

1 |

65 |

42 |

40 |

20 |

20 |

| 3 |

430 |

360 |

325 |

230 |

90 |

| 6 |

1150 |

970 |

830 |

375 |

110 |

| 10 |

2000 |

1350 |

1000 |

420 |

125 |

| VEM-100 |

ELEE00020 |

20 |

1 |

70 |

50 |

45 |

35 |

25 |

| 3 |

530 |

440 |

426 |

335 |

225 |

| 6 |

1400 |

1200 |

1050 |

730 |

310 |

| 10 |

2600 |

2200 |

1700 |

880 |

330 |

| VEM-150 |

ELEE00011 |

40 |

3 |

700 |

580 |

550 |

480 |

390 |

| 6 |

1810 |

1650 |

1580 |

1400 |

1100 |

| 10 |

5800 |

4350 |

3910 |

3000 |

1850 |

| 18 |

7104 |

5760 |

4992 |

3840 |

2400 |

| VEM-200 |

ELEE01251 |

40 |

3 |

1050 |

950 |

910 |

850 |

750 |

| 6 |

2960 |

2930 |

2620 |

2520 |

2090 |

| 10 |

7740 |

6630 |

6410 |

5400 |

4380 |

| 20 |

15400 |

13560 |

13080 |

10960 |

8180 |

e (mm): thickness of the piece to hold

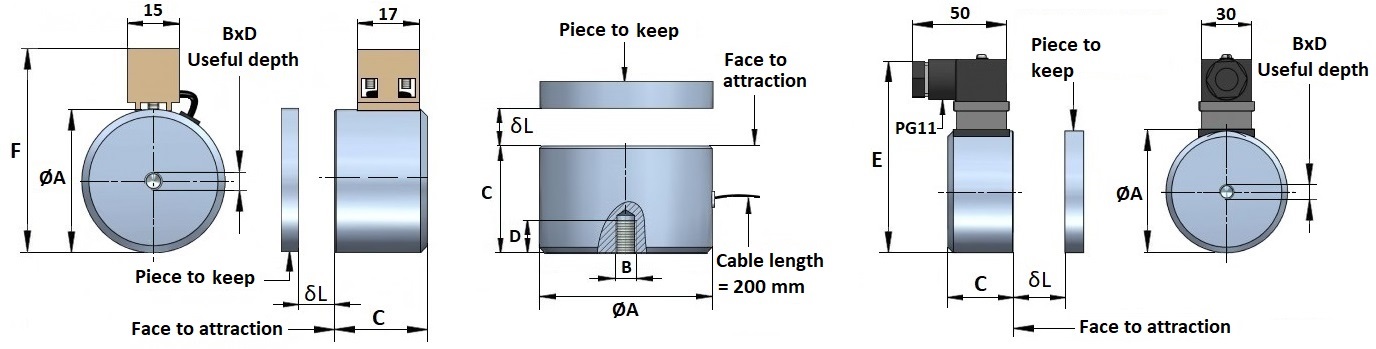

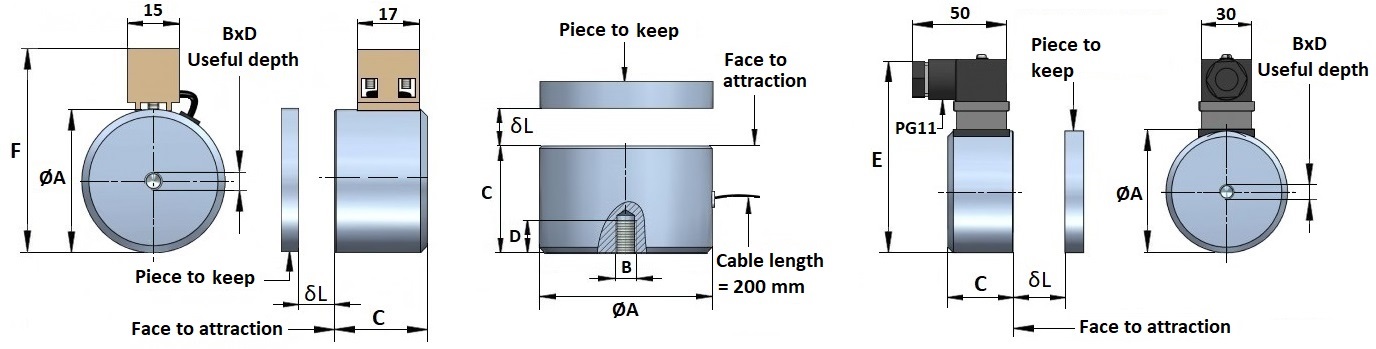

Standard sizes:

Terminal block: Free terminals: Connector ( C ):

Ref: IMAVEM ( type ) B-V-ED% Ref: IMAVEM ( type ) B-V-ED% Ref: IMAVEM ( type ) B-V-ED%

| Model |

Code |

Poids de l'électroaimant (Kg) |

ØA (-0.3) (mm) |

B |

C (±0.1) (mm) |

D (mm) |

E (mm) |

F (mm) |

| VEM-20 |

ELEE00012 |

0.020 |

20 |

M-3 |

15 |

5 |

|

|

| VEM-25 |

ELEV01740 |

0.060 |

25 |

M-4 |

11 |

6 |

|

|

| ELEE0007 |

20 |

| VEM-30 |

ELEE0020 |

0.100 |

30 |

M-4 |

22 |

6 |

|

|

| VEM-40 |

ELEE00017 |

0.200 |

40 |

M-5 |

26 |

8 |

87 |

55 |

| VEM-50 |

ELEE00002 |

0.300 |

50 |

M-5 |

30 |

8 |

97 |

65 |

| VEM-65 |

ELEE00014 |

0.800 |

65 |

M-8 |

35 |

12 |

112 |

80 |

| VEM-80 |

ELEE00013 |

1.300 |

80 |

M-8 |

38 |

12 |

127 |

95 |

| VEM-100 |

ELEE00020 |

2.000 |

100 |

M-10 |

43 |

15 |

147 |

115 |

| VEM-150 |

ELEE00011 |

6.400 |

150 |

M-16 |

56 |

24 |

197 |

165 |

| VEM-200 |

ELEE01251 |

13.400 |

200 |

M-20 |

70 |

35 |

247 |

215 |

Important: the clamp screw must not exceed the dimension D.

* On request, can be manufactured to any size, voltage, duty cycle, etc.

Remarks:

CE-products meet the standards for low voltage 73/23. Compliance to EMC 89/366 EEC should be ensured by the user.

When used for lifting and handling of loads a minimum safety factor of 3 should be used, the weight of the load must be at least one third of the holding force.

When disconnected the remanence can reach values of up to 10% of the force.

Fields of application:

These electromagnets are used, among other applications, to handle and manipulate ferromagnetic objects in industrial robotics, for positioning of parts, for maintaining fire doors, ventilation and general safety.

Recent Comments