Magnets to fight malaria

John Lewandowski, un estudiante graduado en ingeniería mecánica en el Instituto de Tecnología de Massachusetts , ha inventado una máquina que utiliza imanes y rayos láser para identificar la sangre infectada de malaria incluso en pacientes que no muestran síntomas.

The device is portable, easy to use, and requires no specialized medical training. Each test can be performed in about a minute and costs no more than 25 cents. The parasites that cause the disease consume red blood cells but cannot digest the iron in those cells and it accumulates as crystals in the patient's bloodstream. Magnets in the device create a magnetic field around the blood sample while a low-intensity laser beam is fired. If the person is infected, the magnetic field will cause the pieces of iron in the blood sample to line up in an orderly pattern that partially blocks the laser light, thus detecting the disease.

The system is being tested in Peru and India. If the trials are successful, the machine is expected to be launched on the market later this year at a price of approximately €1,700. We at IMA are pleased that magnetic technology is also being used for disease detection and wish John Lewandowski's team every success.

Boston Globe story published on 4 May by Hiawata Bray: http://goo.gl/oIzz3t

IMA will build a magnet factory of 5,000 m².

IMA's magnet factory is currently located in Mollet del Vallés, but at the end of 2016, we will move part of our production to Ripollet. In January 2015 we started the construction of what will be the largest magnet factory in Spain. The factory will have more than 5,000 m2 and will be equipped with the best technological innovations.

IMA has more than 25 years of experience and we are currently leaders in the magnetic sector throughout Europe.

We specialize in the manufacture of magnets and magnetic products.

Thanks to this acquisition we will increase our business activity by tripling our production capacity to offer the best solutions to our customers and to satisfy all their needs in the best possible way.

Throughout the history of the IMA magnet factory, we have actively collaborated with our customers and have always invested in research and development, which allows us to have a deep knowledge of the sector and to develop projects of the highest level with all our customers.

We currently export 70% of our production and have clients who are world leaders in the sector. Through our production centers in China and Italy, and together with our subsidiaries in France and Germany, we offer an efficient, precise, and fast service to all our customers in more than 60 countries.

Maglev, the train that levitates with permanent magnets

Japan is rejoining the high-speed train race with a magnetic levitation train, i.e. a "Maglev", short for magnetic levitation. This means that this type of train floats thanks to permanent magnets replacing the iron previously used in the tracks. These permanent magnets are very similar to the ones we manufacture at IMA Magnet Factory.

The Maglev has broken the world speed record by reaching 603 Kp/h and managed to stay above 600 Kp/h for 11 seconds. Unlike conventional trains and railways, the Maglev has no tracks, which allows it to reach such speeds. Friction with the tracks made it impossible for the train to reach such a high speed.

How does the Maglev train work?

The magnetic levitation train travels inside a u-shaped concrete beam-guideway. It is held in the air by powerful electromagnets that guide, propel and hold it in the air, making it the first train that flies. As Iñaki Barrón, director of High Speed at the International Union of Railways, explains: "The technology is based on the simple principle of magnetic attraction and repulsion: the two poles of a magnet attract if they are of different signs and repel if they are of the same sign. The operation of electric motors is based on the same principle. However, a different form is applied to them. This is known as electromagnetic propulsion".

The train has three basic components: a large electrical power source, metal coils lining the tracks, and magnets underneath the train. The difference between the Maglev and the ordinary train lies in the absence of a motor, in addition to the electrical power found in the metal spirals in the concrete guideway, creating a magnetic field that allows the train to move. At its base, other permanent magnets cause the train to float when it reaches at least 100 km/h. As it accelerates, wheels support it and are removed only when the train floats.

Photo courtesy Railway Technical Research Institute

The maglev train competition

A strong competitor to the maglev train has emerged, the "Transrapid". Germany has also developed a magnetic train, but it uses a different technology. The back of the German train wraps around the metal tracks. Electromagnets sit on top of the tracks underneath the train, allowing it to levitate by a centimeter, even when stationary.

The main difference is that the Japanese train uses superconducting magnets, which emit electricity even when the power supply has been switched off. They achieve this by freezing the metal coils at very low temperatures to save energy, but this cryogenic system is not very convenient because of its high price.

Currently, the only commercial Maglev train in operation is in Shanghai (China) and is based on the one developed in Germany. Other countries have plans to build such trains, but many are constrained by the economic costs. It is only a matter of time before Maglev trains are built in several areas and the costs become cheaper.

Who knows, maybe in a few years we will be able to go from Barcelona to Paris in only 2 hours.

Automotive applications for injected magnets

Injected magnets are a versatile and innovative solution for creating magnetic part designs with shapes and characteristics according to customer requirements. They are made by defining a mixture of magnetic materials such as; samarium cobalt, neodymium, strontium, or barium carbonate, which must provide the magnetic attraction capacity, residual induction, and coercive field that the customer has requested. The materials used in this industrial process must be pulverized into very small particles, usually less than 15 micrometers in size, then mixed with a thermoplastic polymer and injected into molds, resulting in parts. The result is a customized magnetic element with high mechanical strength and very tight dimensional tolerances, typical of neodymium and samarium cobalt magnets.

Lighter automotive magnets to meet new challenges

The automotive industry is advancing rapidly intending to create safer, more advanced, and environmentally-friendly vehicles. This requires robust, lightweight materials that can reduce weight to reduce fuel consumption and produce fewer harmful emissions into the environment. They are much lighter, offer high structural and corrosion resistance can be manufactured in any shape allowing for more efficient construction, saving space, and, above all, have exactly the technical characteristics requested by engineers.

Practical applications in the automotive industry.

Remotely opening the vehicle doors, lowering a window, activating the glove box courtesy light, operating the ABS system, opening the sunroof, using the cruise control system, parking using the autonomous system, receiving engine parameters in the control unit, using the electric brake, operating the position sensors, detecting the seat belt locking and many other functions usually performed by automotive systems is possible thanks to these injected automotive magnets. Although there are currently many applications of injected magnetic elements in the automobile, in the future there will be a strong increase in their installation, as it is expected the massive implementation of autonomous driving systems and the increase in the production of hybrid and electric vehicles.

Manufacture of customized magnets

The industrial process of plastic injection molding of magnetic materials makes it possible to produce parts in any shape, as long as it is possible to build a mold, including flexible elements, magnetic strips, and magnetic tapes. But, even more, important is the possibility of creating magnets with customized magnetic properties at the customer's request, being able to manufacture magnets with defined characteristics for a specific function. The possibilities are very wide, being able to create pieces with high attraction power, typical of neodymium magnets, or elements with slight fields and inductions to obtain other purposes.

IMA is a manufacturer of magnets and magnetic elements closely linked to the automotive sector and its auxiliary company, a reliable and valuable supplier, is very much to be taken into account to make any magnetic element manufacturing project a reality.

What is the difference between a permanent magnet and an electromagnet?

Before trying to explain the main differences between a permanent magnet and an electromagnet, we believe it is necessary to define, in a very simple way, what each of them consists of and how they provide their ability to magnetize.

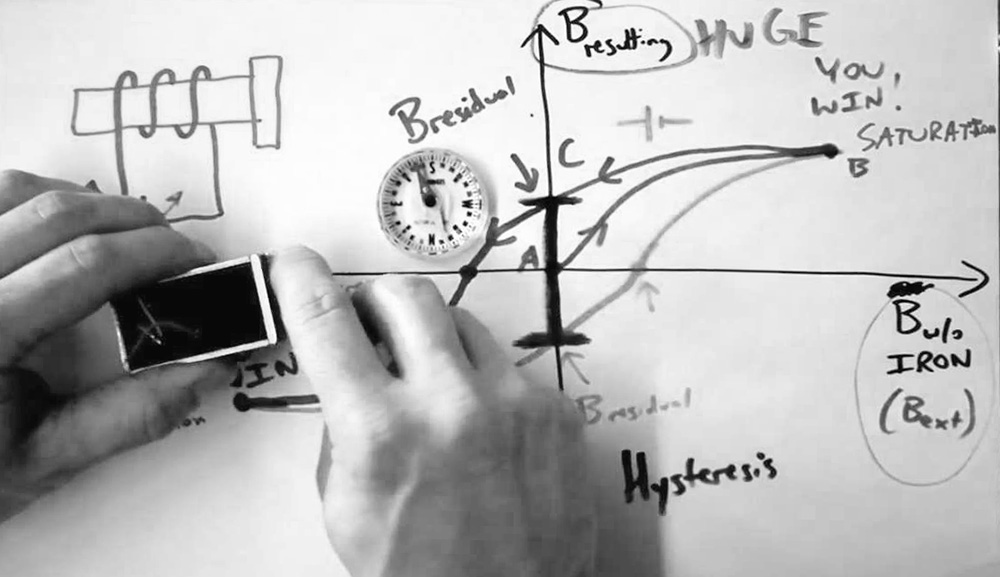

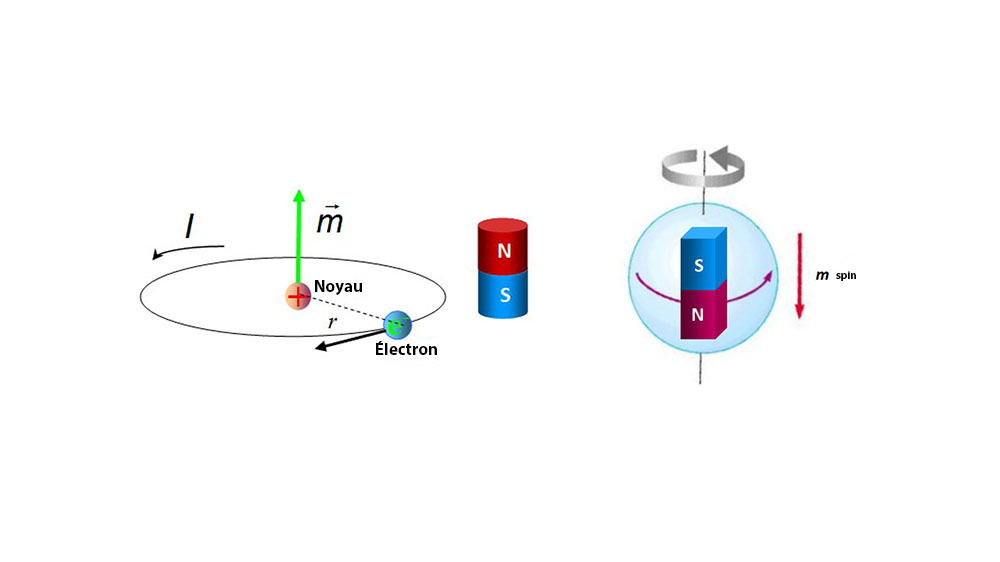

On the one hand, we must bear in mind that in an electromagnet the magnetic field is produced by the current that ends up reinforcing the iron core. For this reason, we can be sure that when the electric current that we are applying to the core is disconnected, the strength to magnetize is lost. This is why we must understand that an electromagnet is nothing more than a magnet whose magnetic field is produced by the passage of electric current, which plays a fundamental role in its capacity to generate a magnetic field. Its behavior is very similar to that of a permanent magnet, with the difference that its intensity can be controlled, increased, and decreased, by changing the intensity of the electric current that circulates. When the current stops flowing, the magnetism disappears when it is switched off.

The permanent magnet, on the other hand, does not depend on electric current to function and provide its magnetism. This type of magnet is composed of a ferromagnetic material that is magnetized by the magnetic field outside the magnet. The magnetizing capacity continues even after the magnet is no longer in contact with the external magnetic field.

In such a technological society, where new advances are needed every day for new applications, magnetic materials play a very important role. The use of permanent magnets or electromagnets will depend on the advantages and disadvantages of both, which we will see below.

Advantages and disadvantages of permanent magnets

They do not require a power supply for the production of a magnetic field. As there is no need for electrical energy, it is environmentally friendly. Permanent magnets can be made in different sizes, so it is possible to make magnets of tiny sizes that can fit into small devices.

This type of magnet does not produce magnetic fields at certain temperatures, so it cannot be used for devices that can get too hot. Over time, they can wear out and their magnetic field can be reduced. The magnetic field it produces is fixed, it cannot be varied, so it is not useful for those who need a changing magnetic field.

Advantages and disadvantages of electromagnets

Advantages. They can operate at higher temperatures than permanent magnets and, above all, allow the magnetic field to be changed with an increase in current. This can be done easily and allows the magnetic field to be changed over some time.

Disadvantages. Reaching the desired level requires the use of a large amount of copper winding, which makes it practically impossible to use for devices where there is not enough space. On the other hand, there is also the fear that the application of too high an electric current could generate a short circuit that would render the electromagnet inoperative.

At IMA we offer our customers different types of magnets, whether neodymium, ferrite, samarium, alnico, or plastic magnets, but also some models of electromagnets, among which we highlight the following: circular, rectangular, and drive electromagnets. On our website, you can find all the characteristics and conditions of each one of them, so that you can choose the one that best suits your needs. Visit our website and ask any questions you may have. We will be delighted to help you.

Applications of magnets in everyday life

Although we are often unaware of it, magnets are constantly present in our daily lives. Magnetic accessories are part of our everyday life. We can find them in very complicated devices such as our car engines and even in very simple processes such as using them to place warning notes on our fridges: the famous magnets that adorn most of our fridges.

Magnetic accessories can be found in our everyday life in the door of a fridge, in toys, and we even use them to orient ourselves, as they are present in compasses used to locate north. As we can see, these magnetic accessories are included in many everyday things, but we must not forget the importance they have for such important devices as those used for magnetic resonance imaging. Magnets can also be found in magnet therapy equipment to treat many types of ailments in the body, using magnetic fields. Magnets can also be found in everyday appliances, such as air conditioning coils or hearing aids, and popular household appliances such as televisions and radios.

Magnets are everywhere. Sometimes we see them directly and sometimes they are part of other devices in which it is more difficult for us to confirm their presence. But they are there.

At IMA we have a wide range of magnets and magnetic accessories for use in your home and workplace. From magnetic paper to steel-impregnated cardboard or plastic-coated magnets. But we also find other types of auxiliary tools that are used in various sectors, some of which we will see below.

Knife and tool holders are commonly used in workshops and factories, as they allow you to keep your material in order in small spaces and in holders that offer great security for frequently used utensils. For workshops or factories, but also kitchens, it is a very practical and safe utensil that can be held in place.

Another application of magnets in our daily lives can be found in magnetic brackets. This is an essential tool during soldering processes, for iron manufacturing and assembly, and allows us to achieve a perfect clamping of components at a fixed 90-degree angle. The arms of the bracket have ferrite magnets embedded in a non-magnetic housing which helps to reduce magnetic stray fields, and also helps to limit the spatter that can occur during soldering.

At IMA we have a wide range of magnet accessories that you can use at home or in your workplace. For your everyday life or your professional development. From magnetic walls, separating walls that have their integrated magnets, to a wide variety of levers with which you can release magnets for boxes and also for magnetic blocks. In addition to all this, we have a wide variety of magnetic panels, although if none of them fits your needs, you should know that our technical department can analyze your needs and thus develop or advise you on the product that best suits your work requirements.

If you have any doubts, please do not hesitate to contact us, as we will be delighted to help you and study your particular case to offer you the solutions you are looking for and need. If you are looking for solutions with magnets, we are specialists with many years of experience in the sector. If you have any doubts, ask us.

Where is the north pole of a magnet?

Magnets can come in many shapes.¡ But in this case, to be able to talk about the north and south poles of a magnet, it will be interesting to think of a rectangular bar magnet. As we have seen on other occasions, magnets can be natural, as is the case of magnetite - which is nothing more than an iron oxide - or artificial magnets, which are those that we obtain by magnetizing a piece of iron that we are going to subject to a magnetic field that we have made through another magnet or through the current that we generate through electricity. All magnets, whatever type they are, are capable of showing, in a clear way, the phenomenon we call magnetism.

Magnets have poles. In a bar magnet, as we have indicated above, we can see relatively simply how iron objects are attracted strongly towards the ends. One of these ends is called the north pole and the other the south pole. The differentiation between the two poles derives from the behavior of the magnet due to the Earth's magnetic field.

In this article, we would like to tell you how to find out where the north pole of a magnet is practical. And so we would like to explain that to determine where the north pole is - when the magnet can move and is not fixed - that it points in a northerly direction. If we use a few magnets and hang them on a string - for example - we can see how they react. As we know that opposite poles attract, we will find that the north pole is a magnetic south pole. Using a compass, it is relatively easy to locate the north pole of a magnet, since the end of the compass needle, which usually points south, will be attracted by the north pole of the magnet.

It is very important, however, that we know what we are referring to when we talk about the north and south poles. Therefore, we can define the north and south poles of a magnet by indicating that the lines that make up its magnetic field run in the direction from the north pole to the south pole. If we want to be a little more specific, we can say that these lines run perpendicularly from the part that is more on the surface at the north pole of the magnet and that they begin to curve as it approaches the south pole, where they reach perpendicular to the surface of the magnetic south pole. In a closed circuit, again the magnetic material of the lines returns to its origin at the north pole.

Another of the terms we usually use when we talk about permanent magnets is the positive or negative pole of the magnet. In this environment, we usually refer to the positive pole like the one that faces north, since the field lines start from that place. However, we must warn that this is a big mistake, since, from a physics approach it is not true, because the magnetic field is a pure bipolar field, which means that there is no magnetic charge of any kind -electrons- that we should see as a single-pole since on the contrary, these magnets have two poles: north and south. This is why we can say that both poles of a magnet are equivalent, there are no single poles.

How are neodymium magnets manufactured?

Before learning about the manufacturing process of neodymium magnets, we would like to point out some aspects that we consider important about this type of rare earth material, as we can say that it is a special material. If we combine it with iron or boron, we can create the strongest magnets available today. On the other hand, due to its nickel and copper coating, it has a very nice silver-colored surface, which makes its use in interiors perfectly compatible with home decoration. The holding force is so strong that it can be used in small spaces. If we compare it with a ferrite magnet, we can say that this magnet, a magnet of the same dimensions, is considerably weaker and its appearance is not as attractive, although it is true that its price is much cheaper.

How are they made?

The manufacture of neodymium-iron-boron (NdFeB) magnets is complicated and requires a great deal of work. This alloy has been made since 1984 due to different research processes, so since that time neodymium magnets with higher power have been built.

For its manufacture, the three elements: iron, neodymium, and boron, are crushed very intensively and melted in a vacuum. The chemical formula of this alloy is known as NdFeB.

The mixture of iron, neodymium, and boron, as well as a few other components, must be crushed very intensively, as mentioned above, and then melted in a vacuum. During the process, the three elements are magnetized and compacted until they form a simple structure, usually in the shape of a cylinder or cube. Once it is in this situation is when it must be heated in a vacuum to allow it to cool over time. Slowly. From now on, the alloy begins to have an increasingly crystalline structure, which will favor the subsequent magnetization. It is at this point that the desired sizes are formed. This raw magnet, as it is known, is then given a copper and nickel-based coating that helps prevent the magnet from oxidizing easily and gives it an unbeatable appearance.

Once we have reached this point, the magnets must be placed in a magnetic coil through which a current will pass for a millisecond, producing a large magnetic field through which the magnets will be magnetized, aligning the molecules and crystals in the magnetic field of the coil.

This is how we at IMA make the neodymium magnets that you can buy. A laborious and highly precise work that makes them one of the most powerful magnets and one of the most successful among our customers. You can find different variants of this type of magnet depending on your needs. Neodymium blocks, neodymium discs, neodymium rings, special geometry magnets, and special segments. Each one of them with its particularities and is specific for a special type of use and customer. Some are more standard and others, such as those with special geometries, are made to customer specifications.

As always, we recommend that you consult us, that you let us know your doubts or suggestions, as we can study your needs and recommend a specific product or, on the contrary, study and make one in particular for your use. We are specialists in magnets and we can find the most professional solution for what you need. Contact us.

How neodymium magnets are made

Magnets are all noted for their magnetic properties. However, not all magnets have the same characteristics, nor are they all the same, nor do they all serve the same purpose. Thus, there are magnets whose magnetization is temporary and may be due to the action of electricity on them, as in the case of an electromagnet. In this type of magnet, the magnetic field can be activated and deactivated at will, changing from being a magnet to not being a magnet at the click of a button. This is incredibly useful if you want to use the magnet to lift and drop objects, but if you are looking for something permanent it is not the best option.

Neodymium magnets: one of the best alternatives

Thus, among all the options available to us when looking for a magnet whose magnetization is permanent, the Neodymium magnets the neodymium magnet is one of the best alternatives available to us, as its magnetization is permanent. Neodymium magnets are made of an alloy of neodymium, iron, and boron, thus generating a composite material with magnetic properties that is much more powerful than any simple magnetic material.

The advent of the neodymium magnet has completely replaced other types of permanent magnets in those sectors where their demand is high, such as in the manufacture of motors in cordless tools, hard disks, and magnetic seals.

How is a neodymium magnet made?

First of all, it should be noted that the manufacture of a neodymium magnet requires a lot of effort. The process begins with the extraction and selection of the three elements that make up the magnet: iron, boron, and neodymium. Once extracted, they are lightly magnetized and then compacted into the basic shape from which they will work, which is usually cylindrical or cubic.

The mixture is then heated in a vacuum (a process known as "synthesizing") and allowed to cool slowly, giving the composite material a crystalline structure that will make it much easier to magnetize later than if it had none.

The neodymium cylinders are then closed or deformed into the exact shape we need for the magnetic compound or parts we are looking for, such as a disc, sphere, or bar. These raw magnets are then galvanically coated with a nickel layer to protect them from rust, as without this coating they will quickly deteriorate and decompose.

The next step would be to magnetize the magnet by placing it in a magnetic coil through which a large current flows. In the magnetic field of this coil, the magnets are permanently magnetized as the crystals of the neodymium magnet itself are aligned in the shape and direction of the magnetic field of the coil.

Finally, the magnetized magnets are sent to the assembly line where they undergo regular and normal quality control operations. Once the quality of all the neodymium magnets is checked and any defective ones are removed from the process, the operators proceed to pack and package each of the magnets in plastic bags and then in cardboard boxes in order to send them to the customers. These magnets, as mentioned above, are permanently magnetized and will never be demagnetized again, making them a reliable part of any mechanism or device.