Products

Permanent magnets have the advantage of operating without additional power factor which provides greater energy efficiency. These magnets are magnetic elements that make up a large part of our product catalog, thanks to their multiple applications. These magnets can be supplied by different types of magnetization, grades, grades and materials.

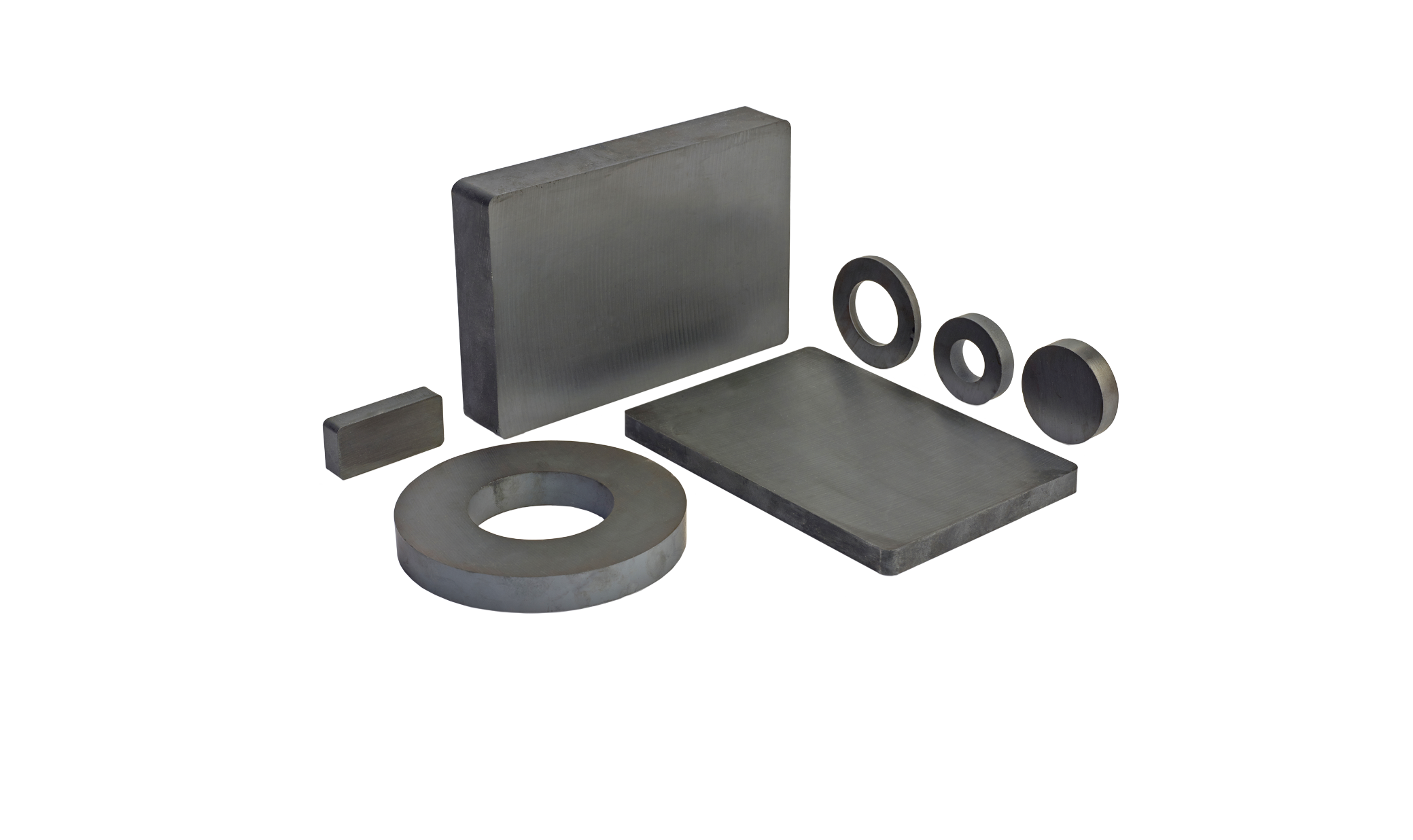

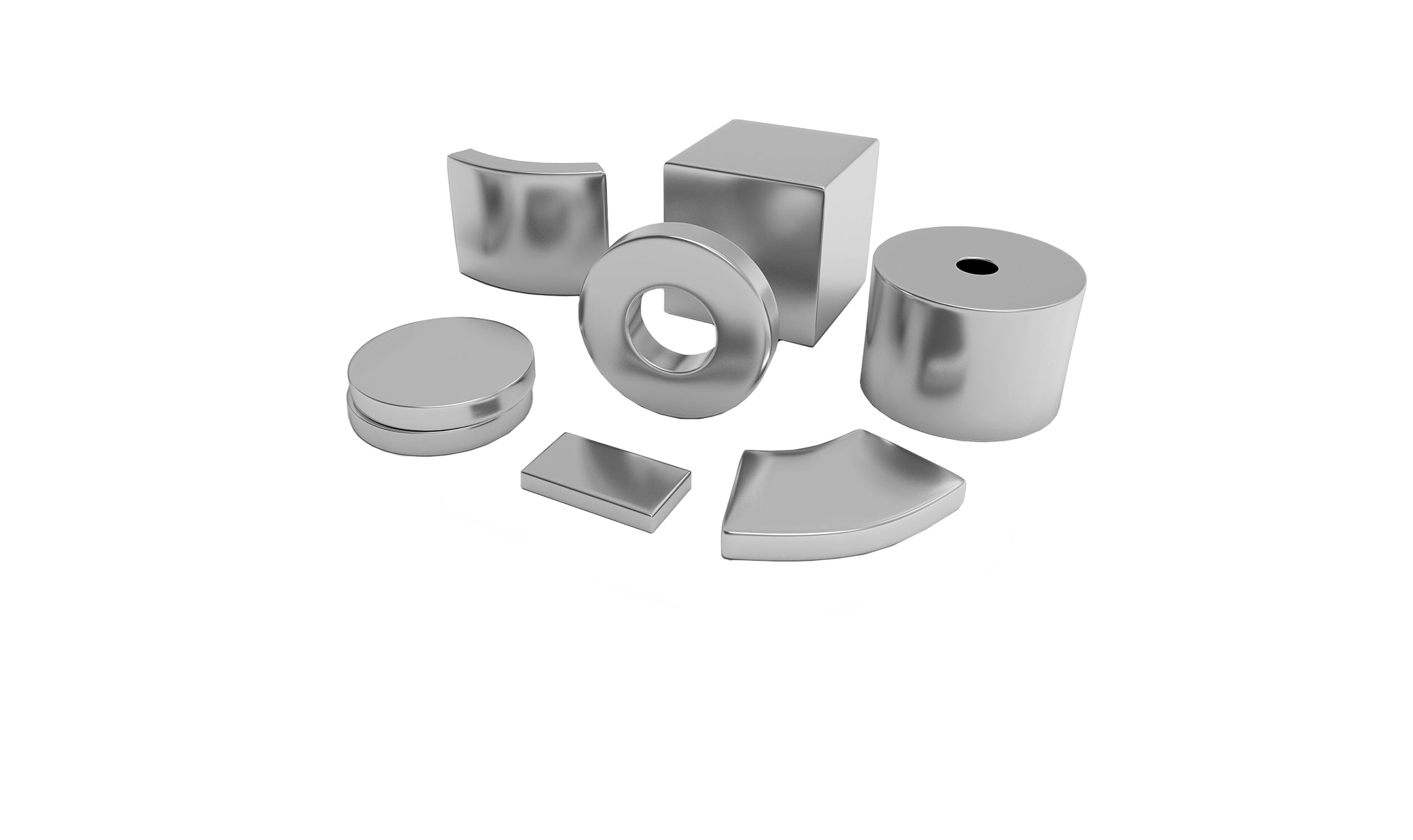

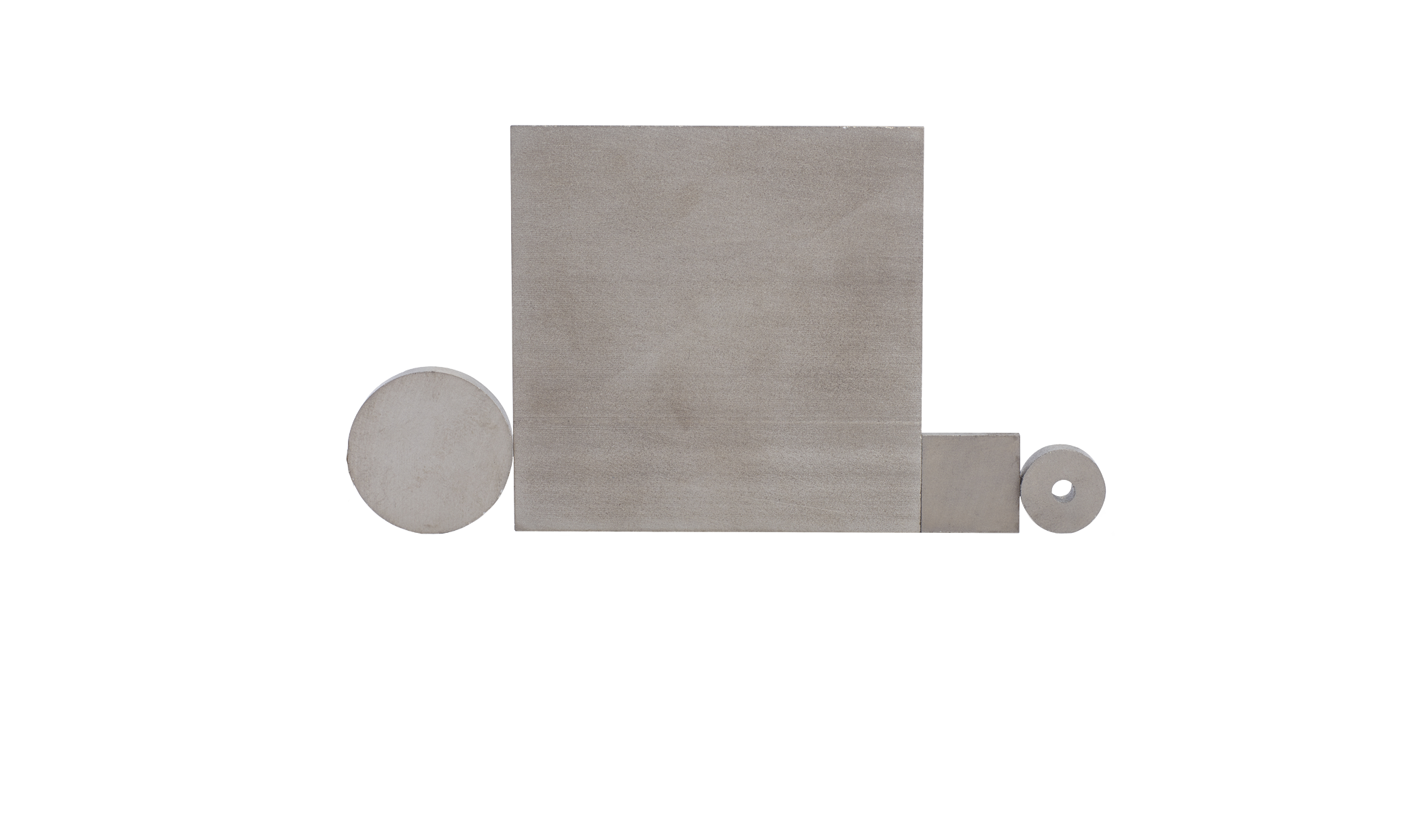

Wide range of permanent magnets made of different materials such as: neodymium, ferrite, alnico and samarium. We also have custom made magnets.

CHARACTERISTICS

There are different factors that describe the quality of a permanent magnet, such as: the strength of the magnetic field or remanence, the resistance being demagnetized or coercivity and the pulling force.

It can also affect the performance of a permanent magnet, the temperature at which the magnetic product is subjected, although there are materials such as samarium or alnico that obtain certain stability at high temperatures. If the maximum working temperature limits are exceeded, the magnet could be demagnetized, for this same reason, a good technical advice is recommended.

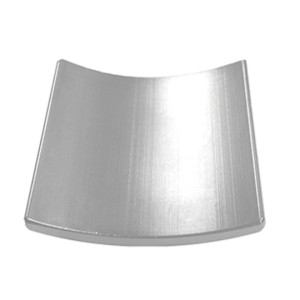

Permanent magnets are produced in very different forms such as: discs, rings, blocks, segments and other shapes, upon request. Majority, permanent magnets are coated to protect them from corrosion and other adversities, thus increasing their performance. There are a large number of coatings, but the most typical are: nickel, Teflon, epoxy, rubber, nylon, among others.

The use of permanent magnets has grown, considerably thanks to the multiple applications in sectors such as automotive, medicine, engines and wind energy… where quality products and certain safety for their uses are required.

If you need high quality magnets, orders of a certain amount with little time or just need a good advice and technical service, you will find the solution in IMA. We have a large stock adapted to the needs of our customers in very varied sectors.

Showing all 14 results