Which coating is the best for your magnet?

Magnetic coating, a necessity

Ferrite magnets, neodymium magnets or even magnetic bases are used for a variety of applications in technology, in industry and also for medical purposes. There is a need to provide magnets with a surface protection against corrosion, the “coating” for magnets.

Types of coatings for magnets

NiCuNi coating: The nickel coating is composed of three layers, nickel-copper-nickel. This type of coating is the most widely used and provides protection against corrosion of the magnet in outdoor situations. Processing costs are low. The maximum working temperature is approximately 220-240ºC (depending on the maximum working temperature of the magnet). This type of coating is used in engines, generators, medical devices, sensors, automotive applications, retention, thin film deposition processes and pumps.

Black nickel: The properties of this coating are similar to those of the nickel coating, with the difference that an additional process is generated, the black nickel assembly. Properties are similar to those of conventional nickel plating; with the particularity that this coating is used in applications that require that the visual aspect of the piece is not bright.

Gold: This type of coating is often used in the medical field and is also suitable for use in contact with the human body. There is an approval from the FDA (Food and Drug Administration). Under the gold coating there is a sub-layer of Ni-Cu-Ni. The maximum working temperature is also about 200 ° C. In addition to the field of medicine, gold plating is also used for jewelry and decorative purposes.

Zinc: If the maximum working temperature is less than 120 ° C, this type of coating is adequate. The costs are lower and the magnet is protected against corrosion in the open air. It can be glued to steel, although a specially developed adhesive must be used. The zinc coating is suitable provided that the protective barriers for the magnet are low and low working temperatures prevail.

Parylene: This coating is also approved by the FDA. Therefore, they are used for medical applications in the human body. The maximum working temperature is approximately 150 ° C. The molecular structure consists of ring-shaped hydrocarbon compounds consisting of H, Cl and F. Depending on the molecular structure, different types are distinguished as: Parylene N, Parylene C, Parylene D and Parylene HT.

Epoxy: A coating that provides an excellent barrier against salt and water. There is a very good adhesion to steel, if the magnet is glued with a special adhesive suitable for magnets. The maximum working temperature is approximately 150 ° C. The epoxy coatings are usually black, but they can also be white. Applications can be found in the maritime sector, engines, sensors, consumer goods and the automotive sector.

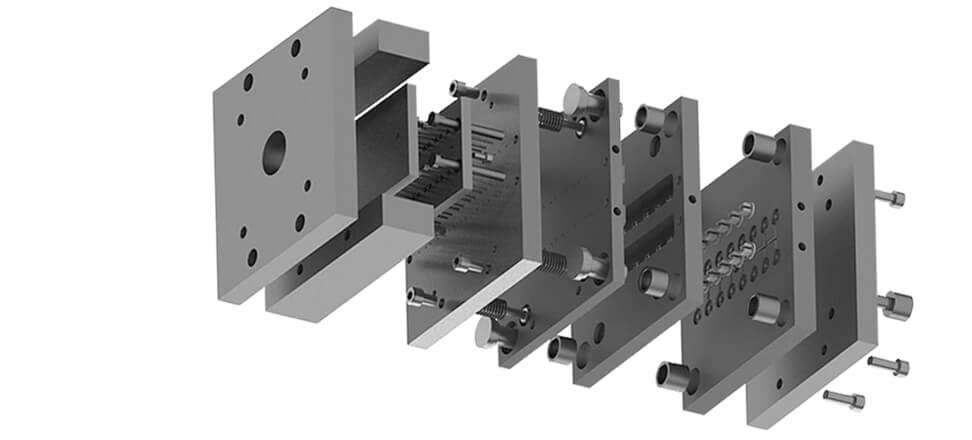

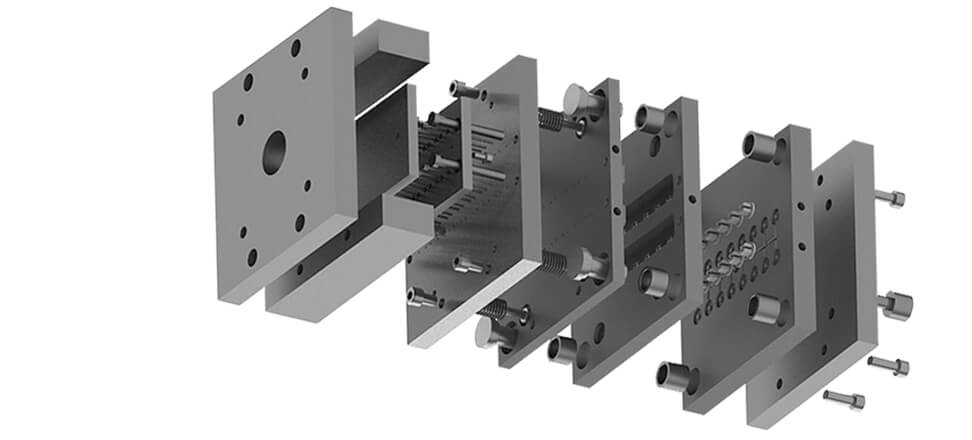

Magnets injected in plastic: or also called over-moulded. Its main characteristic is its excellent protection of the magnet against breakage, impacts and corrosion. The protective layer provides protection against water and salt. The maximum working temperature depends on the plastic used (acrylonitrile-butadiene-styrene).

Formed PTFE (Teflon): Like the injected / plastic coating also provides excellent protection of the magnet against breakage, impacts and corrosion. The magnet is protected against moisture, water and salt. The maximum working temperature is around 250 ° C. This coating is mainly used in the medical industries and in the food industry. Rubber: The rubber coating protects perfectly from breakage and impacts and minimizes corrosion. The rubber material produces very good slip resistance on steel surfaces. The maximum working temperature is around 80-100 ° C. Pot magnets with rubber coating are the most obvious and widely used products.

Rhodium: Rhodium coatings give the magnet very good resistance to scratches and tarnish. The magnet is also protected against corrosion. In addition, the rhodium coating gives the magnet a very decorative appearance. The maximum working temperature is around 200°C. Rhodium coatings are used for jewelry, medicine and the automotive industry.

Titanium Nitrate (TIN): Is also a coating approved by the FDA and is suitable for use in applications in contact with the human body. It is formed by a hard layer with a very strong bond to the magnet. In addition, it provides resistance to most chemicals. The maximum working temperature is approximately 500 ° C and its main use is in the medicines sector.

Copper / Chrome / Silver: This type of coating is mainly used for decorative purposes. The maximum working temperature is around 200°C.

Professional advice on how to protect your magnet Some magnets, such as neodymium magnets and magnetic bases, require adequate surface protection for proper, permanent and trouble-free operation. Which protection is most appropriate in each case individually, will depend on the different conditions of use and application of the magnet. We provide our clients with advice and solutions to obtain the best application of the magnet. We place our extensive experience in the field of magnetism at your disposal. Contact us and we will be happy to answer your question.