Learn more about injected magnets

We call injected magnets those that have been manufactured through ferrite magnetic powders and also rare earths that have previously been incorporated into what we call thermoplastics, among which we highlight, above all, polyamides. They are a type of magnet much more resistant to any type of corrosion than those synthesized materials. We should not overlook the fact that maximum temperatures between 100 and 120 degrees Celsius are achieved.

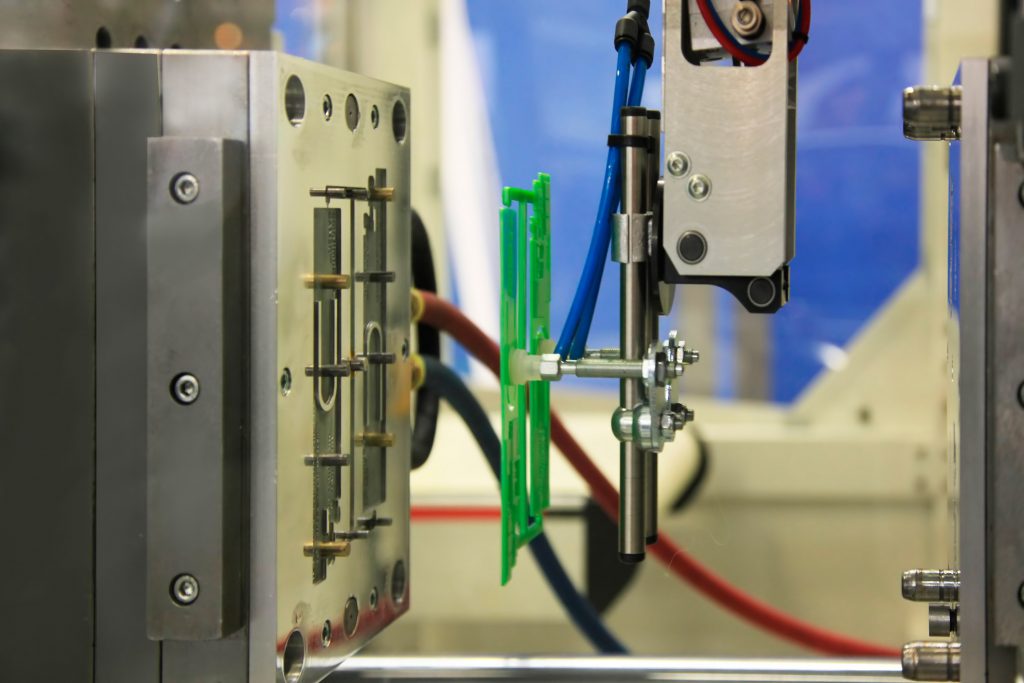

Magnets can be injected or manufactured in special plastic polymers with particles that we have incorporated of ferrite or neodymium. Doing so will allow us to use all the usual possibilities of models for plastics to make designs with shapes and also with a special type of magnetization. Everything made from the needs of the client.

It is because of the different, unique possibilities offered by this technology that we cannot speak of standard sizes, and it is also what allows us to customize the magnet as much as possible according to customer requests and the specific needs of the application that is going to be given to it.

In the injection moulding process, a type of solid binder is used, such as plastic, to which the magnetic type material is attached, providing us with a large number of shapes. The resulting material is isotropic.

Among the main advantages that we can find in magnets that have been moulded by injection we can highlight the following: possibility of making more complex shapes and structures; they are magnets that have low conductivity and also low eddy currents; they are magnets with good tolerance and are more resistant to jumping to compression in situations of servitude; and they allow hybrid versions with combined properties; versions of NdFeb, SmCo, alloy steel and ferrite and also Overmold, mould insert.

Advantages of injected magnets

Among the main disadvantages of an injection molded magnet are the following. The main disadvantage is that these magnets will have a lower magnetic performance than those that have been made by compression in bonded conditions. This happens because the magnetic load is lower.

At present we find injection moulded magnets in many everyday uses of which we are often not aware. From motors, to sensors, magnetic components, etc.

We would like to highlight the injected Neodymium magnets, as they are currently the most used and requested by customers. These, in addition, are produced using the design and special needs of the customer, so they have an exclusive use.

We must remember that it is currently possible, through the process of stamping, both injection and compression, the mixture of plastic materials with powders with a greater or lesser load of Praseodymium-Neodymium. For this reason, it is possible to create, at the customer’s request, a type of mixture with very personalised characteristics according to the required indications, both with very small tolerances and quite the opposite.

These types of magnets have magnificent mechanical properties that will make it possible to reach precise and adjusted tolerances for each need, which makes it possible to achieve a perfect balance and, furthermore, they allow for complicated geometries that adapt perfectly, as the peculiarities and needs of the customers have been taken into account for the realisation of this.At IMA we manufacture plastic magnets for many companies in different fields, such as manufacturers of electric motors, household appliances or automobiles. Maximum temperatures of between 100ºC and 120ºC are obtained and allow us to solve the specific needs of each client.