How to create Eddy currents?

Eddy currents are also known as “Foucault current” in English. These are electrical currents which, using an Eddy current separator, form a variation over time, cutting even the smallest non-ferrous metals.

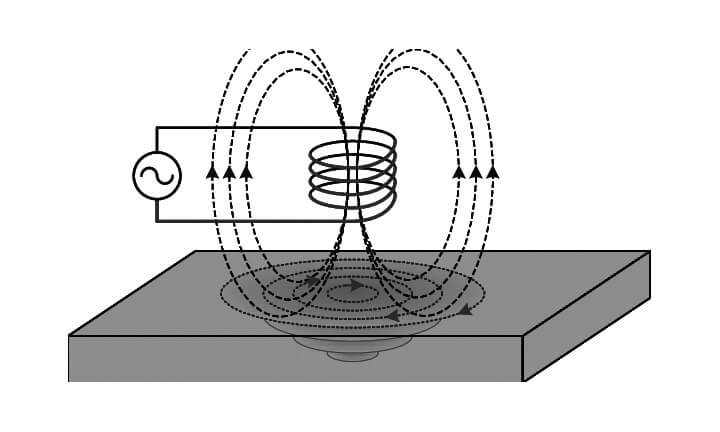

First, let's clarify how it works. For this we must look more closely at the principle and the functioning of the Eddy currents. These are different electric currents that are created inside a so-called conductive mass. They can be created in two different ways: either through the displacement of the conductive mass inside a magnetic field. Either with the help of an external magnetic flux which induces a variation over time.

The result of these variations is the creation of vortices if the magnetic field is constant over time but spatially inhomogeneous and the conductive mass moves. The current name for the Eddy currents was chosen because the current Eddy lines are independent and look like vortices.

These vortices create a magnetic field, which can use high frequencies to move the current from the center of our conductor. If you add an electrical resistance, it becomes hot because of this effect. Using Maxwell's equations, the active forces in this scenario and the exact current distribution can be calculated. We have already talked about Maxwell's equations before in our blog.

To form an Eddy separator, you need a chain conveyor system and a magnetic rotor that is attached to the end of the conveyor belt and operates at high speed. In this way, an induction field can be created, which in turn produces a rapidly changing magnetic field. All electrically conductive particles, which are guided on this conveyor belt system, are briefly magnetized by the magnetic field and, therefore, are "cut" and sorted automatically. Non-ferrous metals, such as aluminum, brass or copper, can be separated from the rest. In general, materials with a lower density and good electrical conductivity can be cut better with stray currents.

Where is an Eddy separator used?

Non-ferrous rotary burs are used in many industrial sectors.

For example, in the glass recycling industry, where stray currents eliminate

aluminum closures. In wood production, brass handles and hinges are classified

directly in the electronic and household waste treatment section.

Depending on the use we want to make, the basic model of the Eddy separator can be improved with additional parts. For example, you can add a separation container or a partition. It depends on the needs.

If you have any questions about the non-ferrous rotary burr or if you are interested in other products from our store, you can contact us at any time and without any commitment.